Polypropylene Sheets is popularly known as a thermoplastic material. It is regarded as an economical material that provides one a combination of electrical, chemical, physical, mechanical as well as thermal properties. These properties are not present in any other kind of thermoplastic material.

Singhal Industries Private Limited is a leading manufacturer of PP sheets. They supply premium quality sheets. Polypropylene sheets are very beneficial since it possesses suitable dimensional stability and also constitutes an outstanding combination of different machine cut features.

The PP sheets have high demand in the international and domestic market because it’s highly resistant to fatigue. The PP sheets manufacturer can also customise the sheets according to the specifications of the customer. Moreover, customers order such sheets primarily for printing industries.

What is the use of Polypropylene sheets?

PP sheets are excessively used in the markets because it is highly resistant to corrosive environments and it feature lesser density. These sheets could be freely machined and welded.

The structure of polypropylene is very rigid and due to its relative cheapness, it serves the best purpose in a wide range of applications.

Its perfect reliability and good resistance to chemicals make it suitable for the furniture market, automotive industry, consumer goods as well as different industrial applications like custom wire markets.

Some of the common uses of polypropylene sheets include:

#1. Packaging Applications: The strength and structure of polypropylene are what makes it ideal as well as a cheap packing application.

#2. Fibres and Fabrics: The utilization of Polypropylene is done in a host of fabrics and fibre applications such as a spun-bond, raffia/slit film, continuous filament, tape, staple fibres, strapping as well as bulk continuous filament.

#3. Consumer Goods: It is widely used for different consumer goods such as toys, translucent parts, appliances, housewares, luggage and furniture.

#4. Industrial Applications: The huge tensile strength of PP’s structure along with its resistance to chemicals and high temperature makes it suitable for Returnable Transport Packaging, tanks, pipes as well as sheets.

#5. Automotive Applications: The features such as nominal cost, mechanical characteristics and weldability make it very convenient to use. It is commonly present with indoor trims, battery cases, instrumental panels, fender liners, interior trim as well as bumpers.

#6. Medical Applications: It is also widely used for different medical applications such as disposable syringes, medical vials, specimen bottles, diagnostic devices, food trays, Petri dishes, pill containers as well as intravenous bottles. Both bacterial and chemical resistance makes it so useful for medical use.

What are the different properties of Polypropylene?

Some of its different properties which you should be aware of while opting for coating for the custom wire basket are listed below:-

#1. Water Absorption

Its properties include its high impermeability to water. During the 24-hour soak testing, the absorption of less than 0.01% is accounted for by the material of its weightage in liquid. This makes it suitable for immersion applications where the protection of the underneath basket material is done from getting exposed to harmful chemicals.

#2. Chemical Resistance

Between the comparison of polypropylene and polyethene, polypropylene is highly resistant to chemicals. It has stronger resistance to various alkalines, organic solvents as well as acids. Moreover, the material is also susceptible to any attack from aromatics, oxidizing acids as well as chlorinated hydrocarbons.

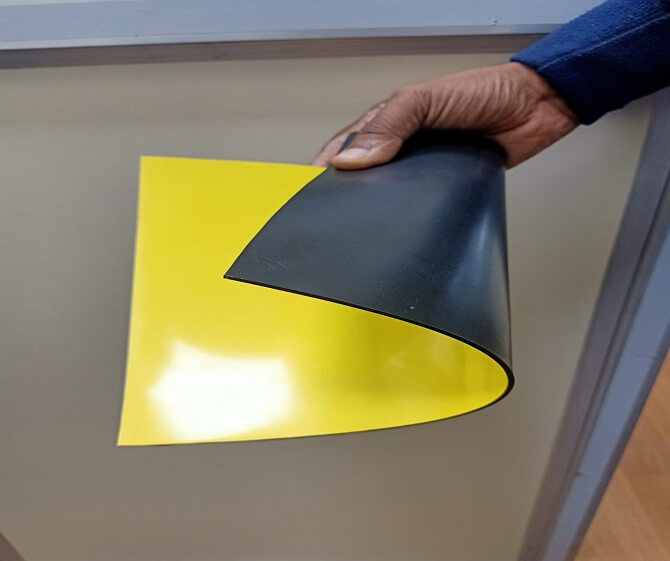

#3. Hard Surface

Through the Rockwell R scale, the measurement of polypropylene’s hardness is calculated. It is placed on the higher end of the soft materials to measure it properly on the scale. This defines the semi-rigidity of the material. That’s why it bends often and is very flexible.

#4. Tensile Strength

In comparison to other materials, it possesses commendable tensile strength which is around 4,800 psi. This is why the materials can easily withstand heavy loads even though it’s quite light weighted.

#5. Operating Temperature

Its maximum operating temperature should be around 82.2°C or 180°F. Below this temperature, the performance of this material might be compromised.

#6. Tolerance

While polypropylene possesses good tensile strength, its resistive impact leaves something to be desired during its comparison with polyethene.

What are the specifications of the PP sheet?

Following are its specifications enumerated:-

- PP sheets are thick around 0.2 mm to 100 mm.

- The width of the PP ranges between 100mm to 2500mm.

- Although the usual colour of the sheet is natural white it can be changed according to the specifications of the customer.

- It can be purchased in the form of flat sheets as well rolls.

Conclusion:-

Polypropylene is one of the advantageous plastics to mould injection and is generally available for this in the formation of pellets. Polypropylene can be easily moulded even though it is semi-crystalline, and due to its low melt viscosity, it can flow very freely. We are a leading abs plastic sheet manufacturers also.

Also Read : What is pp Sheet ?

Also Read : About Plastic Sheet Products

Also Read : Seven key facts about PP sheets that you should know